|

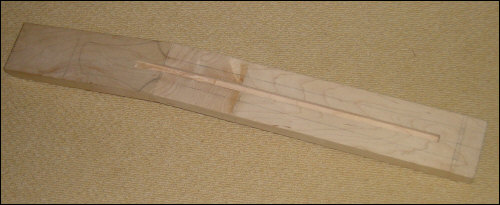

The neck blank with the neck from my Jackson resting on top of it to

give an idea of size. First thing that needed doing was the cutting of

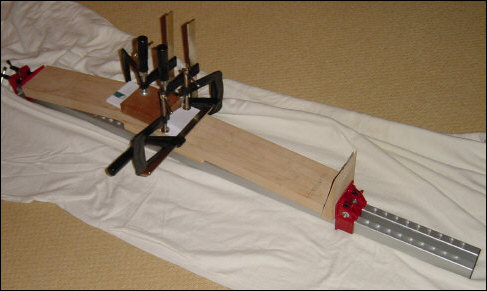

the scarf joint, once this was achieved I had to rig up the clamps in

such a way that it all stayed flat and correct.

As you can see, it had to be held so that the pressure from the clamps

holding the actual joint together didn't cause it to slip out of place,

and so the two long clamps were used to hold it properly lengthways.

Next up was the truss rod slot...

Here you can see the truss rod slot routed and just about make out the

tracing of the neck design on the blank itself. The slot was routed

using a the routers own guide fence along the side of the blank to make

sure the route stayed centred, and was done in several passes to

minimize wear on the router bit.

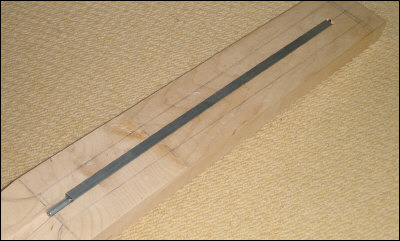

As you can see, the truss rod fits neatly in the slot.

The Fingerboard for the guitar was ordered pre-slotted from the luthier

section of

CraftSupplies and is a particularly nice piece of birdseye maple.

Here's a pic of part of the fretboard lightly wetted with water to

highlight the grain slightly.

Before the fingerboard was attached to the neck blank I rough profiled

the neck with a jigsaw, unfortunately I forgot to take any pictures of

this. In retrospect I should have profiled the fingerboard before gluing

it to the neck blank, as this would allow me to use the fingerboard as a

guide template for the router to trim the neck flush, and would have

avoided a lot of hassle.

The fingerboard gluing up.

|